Main technical parameters

|

(speedis influenced by cup size, paper quality, and thickness) |

Paper cup size |

Each set of molds produces a cup of different sizes, and molds need to beeplaced for cups of different sizes |

Powerrequirements |

3phase 380V 50Hz |

Workingpressure |

最小壓力:0.6千克力/平方厘米氣耗:0.5立方米/分鐘 |

Total power |

28Kw(實際消耗功率18kw/Actualpowerconsumption18kW) |

Machine weight |

3200Kg |

Packaging size |

機(jī)器:2900mx1720mmx2400mm收杯架:1000x850x2200mm |

Raw material |

PE/DUal PE/PLA Coated Cup Paper, Aluminum Foil Paper |

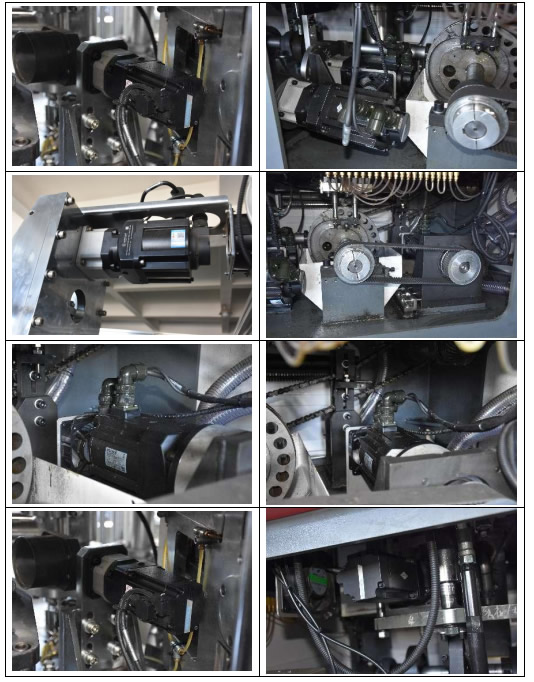

The machine adopts 8 servos to work with the machinery to keep the machine working accurately and make no mistakes when running at high speed.

Rotary suction device

The rotating paper suction device is more stable than ordinary paper suction, and it does not jam paper during operation, and is more suitable for high-speed operation.

Rotary suction device

Fan paper interface hot air preheating device

The hot air interface preheating is located on both sides of the fan paper, and the hot air preheater preheats the sealing part of the paper to ensure that the ultrasonic sealing can better glue the paper without leaking when the machine is running at high speed.

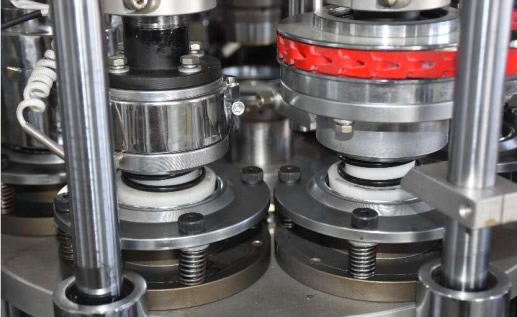

Double flanging device

The double edging is more suitable for high-speed operation, and the heater makes the paper cup more beautiful, no burst, and the cup is tighter.

Bottom 2 rotation knurled

Two rotating knurls make the bottom more cohesive and the bottom of the cup does not leak.

Inlet photoelectric inspection

In the operation of the machine, paper jam, lack of paper, adhesion, blockage and other situations, the machine will automatically stop running, to ensure the safety of parts, no damage.